Propulsive efficiency improved

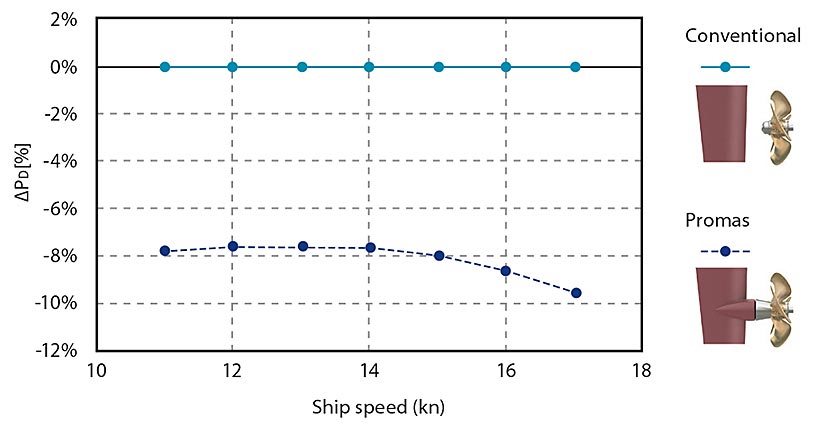

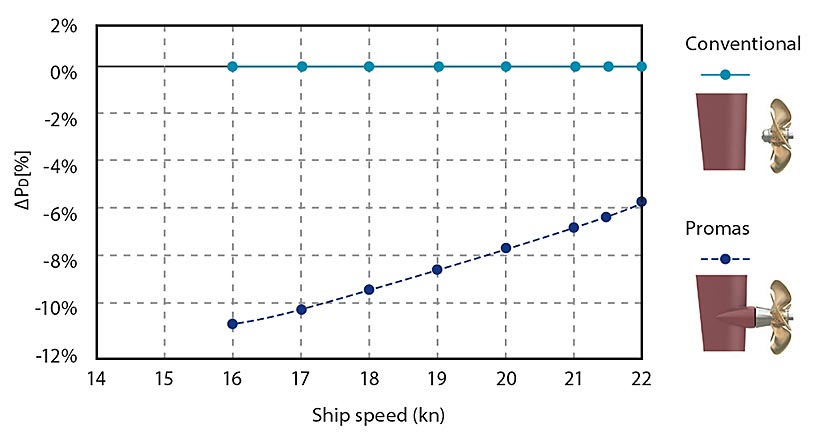

In general, the Promas efficiency gain is in the region of 3 – 8 per cent for single screw, and 2 – 6 per cent for twin screw vessels. Comparison tests between a conventional propeller-rudder system and Promas are shown in the graphs below.

Relative power delivered vs. ship speed - single screw vessel

The rudder area, profile shape and position are identical for the conventional and Promas cases in the graphs below. So the increase in efficiency shown is the pure effect of the bulb, hubcap, rudder twist and adapted propeller design.

Relative power delivered vs. ship speed - twin screw vessel

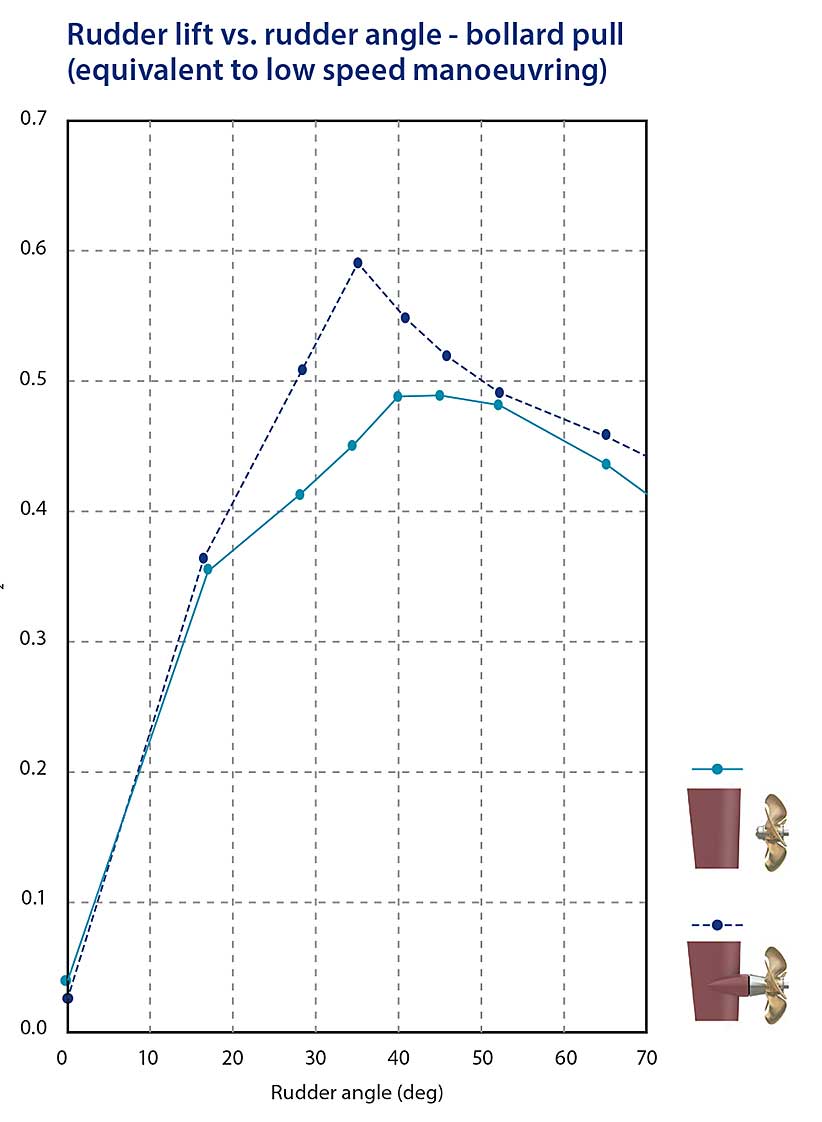

Improved manoeuvring at low speed

At low speed manoeuvring ie. harbour manoeuvring, a maximum side force and a maximum rudder drag is important. The graph below shows the non-dimensional lift against rudder angle for a single screw vessel.

Rudder lift vs. rudder angle - bollard pull(equivalent to low speed manoeuvring)